In its pursuit for a low-cost DAC solution, Carbyon invented an ultra-fast CO2 capturing material. Where conventional materials need hours to capture CO2 from air, Carbyon’s can do the same in only a few minutes. In this way, each kilogram of their material captures up to 5 ton of CO2 annually. This allows for compact DAC machine design, resulting in a CAPEX cost below $50/ton. Initially the fast-swing process suffered from collateral water adsorption, introducing an energy penalty. The recent breakthrough discovery massively reduces water uptake, resulting in an energy demand below 2,500 kWh/ton, while preserving their CAPEX benefits.

Carbyon is the first Direct Air Capture company to merge low CAPEX with low energy demand, thanks to their unique fast-swing process.

“Our relentless stare-down with Mother Nature’s laws of physics finally gave us the insights into how to solve this puzzle. This is a major team achievement, 2.500 kWh/ton is a challenging milestone for any DAC technology. Demonstrating this with an all-electric, low-CAPEX technology puts Carbyon in pole position to reach the $100/ton target that the market is looking for. Nothing can stop us now!” – Hans de Neve, founder and CEO of Carbyon

Carbyon’s breakthrough led to fundamental understanding of working principles empowering them in their mission to even further reduce the technology’s energy demand. The company is rapidly growing and is currently developing their first engineering-scale machine, that will be validated in the field together with pilot partners. So far, the company has raised $10M and is currently raising a Series A round to finance upcoming activities.

For more information and inquiries, please contact

Beatrix Bos

media@carbyon.com

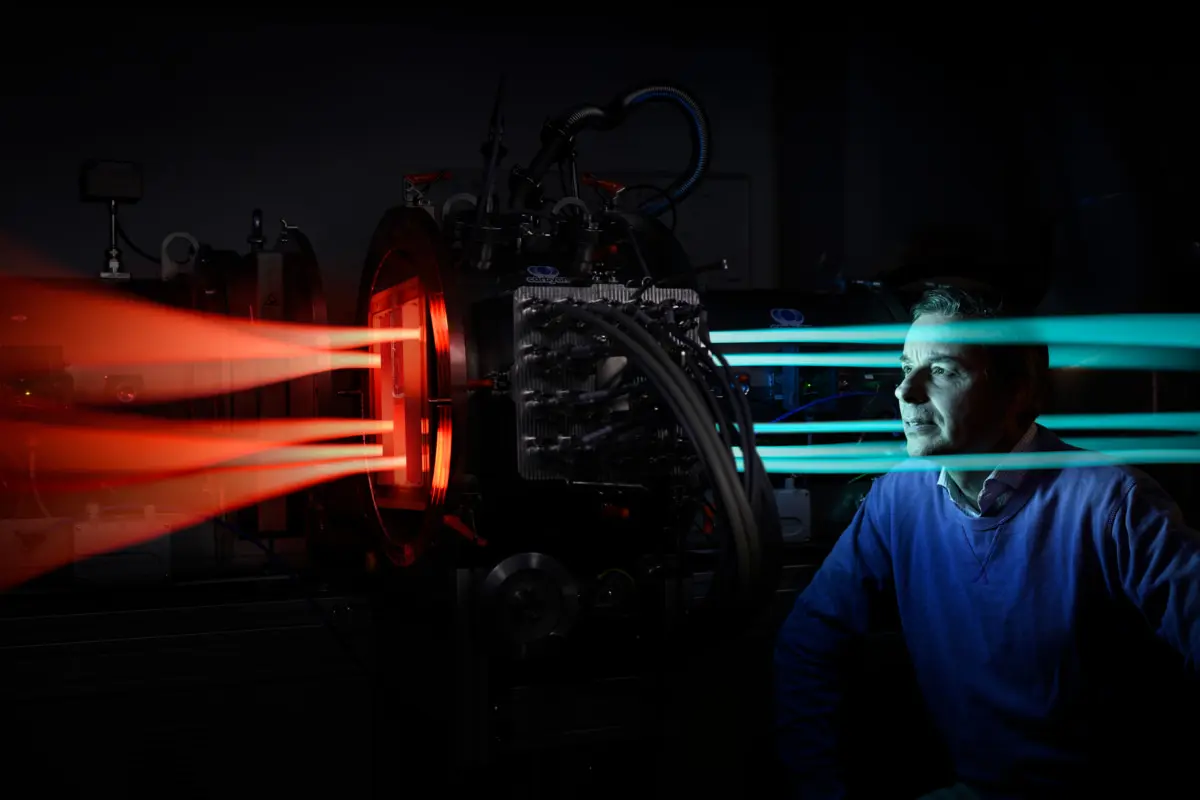

Photo by Bart van Overbeeke.